Forklift Propane Tanks: Sizes, Refilling, & More

Propane-powered forklifts have moved products around warehouses for decades now, and in today's "just-in-time" economy, they’re more valuable than ever.

Warehouse and distribution facility managers have plenty to worry about, and waiting for electric units to charge shouldn’t be one of them. As distribution centers look for ways to keep up with demand and save money while also meeting strict nationwide indoor air quality standards, propane becomes the easy choice.

Have you been considering propane to power workplace forklifts? This guide will walk you through propane tank sizes and materials, how to refill with ease, and much more. Let’s get started.

Forklift Propane Tank Sizes

Propane tanks for forklifts come in two sizes:

- 8-gallon (33-pound)

- Capacity: Holds approximately 7.4 gallons of propane.

- Dimensions: 29″ in height and 13″ in diameter.

- 10-gallon (43-pound)

- Capacity: Holds approximately 10 gallons of propane.

- Dimensions: 33” in height and 12.5” in diameter.

Approximately 90 percent of propane-fueled forklifts utilize an 8-gallon (or 33-pound) propane tank that lasts an average of eight hours. Forklifts that run on a 10-gallon (43-pound) propane tank are used to power larger forklift engines. Roughly five percent of Ferrellgas’ forklift tank exchange customers operate lifts with these larger-sized tanks. Not unlike larger gasoline-fueled vehicles on the road today, these larger forklifts aren’t as energy efficient as the smaller models, with a 10-gallon propane forklift tanks running for about six hours.

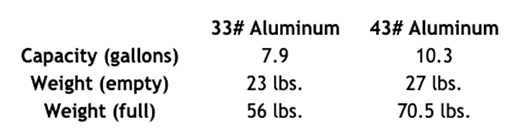

Tank Materials and Weight

Both steel and aluminum tanks are available to propane forklift operators. Each holds approximately eight gallons of propane, but the difference in materials can create quite a difference in weight. A steel forklift cylinder weighs approximately 35 pounds when empty and 69 pounds when full. An aluminum forklift tank on the other hand, weighs approximately 22 pounds when empty and 56 pounds when full.

Table via https://www.propane101.com/

How to Replace a Forklift Propane Tank

Changing a tank can be quick and easy and should always be done with care. Follow these general guidelines for safe forklift cylinder changeout:

- Secure forklift for possible movement.

- Never exchange cylinders where smoking or other sources of ignition are present.

- Wear protective gloves. Liquid propane can cause freeze-burns.

- Keep your hands and face away from relief valve opening.

- Shut off liquid service valve by turning clockwise (to the right) and run engine until fuel in the line has been used. Shut off the ignition.

- Disconnect and remove empty cylinders from the forklift.

- Check full cylinders for any sharp dents, gouges, and visible leaks.

- Check inside safety connector for the presence of a rubber washer located at the opening and for an “O-ring” located inside the connector.

- Never throw, drag, or roll a propane cylinder.

- Most cylinders weigh between 50-60 pounds, so use proper lifting techniques.

- Position horizontally mounted cylinders so the locator pin on the tank bracket engages the pinholes on the cylinder and the relief valve is pointed upward.

- Clamp the cylinder securely.

- Inspect the fuel line for any cracking, bulging, fraying, or other signs of wear. Include inspection of the hose coupling for signs of wear (such as threads appearing sharp or showing damage). This coupling shouldn't have any O-rings or washers in it.

- Check to ensure the liquid service valve on the cylinder is closed. Connect the safety coupling by turning clockwise (to the right). This connection should be firmed hand tight.

- Slowly crack open the main shutoff valve by turning counterclockwise (to the left). When the fuel line has been pressurized, finish opening the valve all the way.

- Check the connection for any visible or audible leaks.

- When the forklift cylinder is to be attached or at the end of the shift, close the liquid service valve by turning clockwise (to the right) and run the engine until the fuel in the line is used. Never leave an unattended machine with a pressurized fuel system.

- Identify defective cylinders with the tag provided.

- For additional information, refer to your Propane Safety Information for PERC and the Safety Data Sheet (SDS).

For more information about forklift cylinder changeout, contact your supplier.

Please note: This information is general in nature and is for informational use only. For specific applications, contact your forklift dealer or refer to your Forklift Operator’s Manual.

Forklift Propane Tank Safety Tips

Forklift tanks are safe when properly stored, inspected, and handled. Here’s how to protect your people and equipment:

Forklift Tank Storage

Per OSHA and NFPA 58, propane cylinders must be:

- Stored upright in a secure cage or rack

- Placed in a well-ventilated outdoor space that meets minimum distance requirements

- Kept away from ignition or heat sources, stairways, exits, or other high-traffic areas

- Clearly labeled and protected from unauthorized access

- Stored with their service valves closed

Please note: This is not an exhaustive list of storage requirements. The team at Ferrellgas can help ensure all requirements are met during initial installation service. Please contact your local account manager or sign up here for more information.

Forklift Tank Replacement PPE

The OSHA Personal Protective Equipment Standard (1910.132) requires employers to outline the PPE necessary, as well as provide training on how and when to use the identified PPE, to perform tasks such as forklift propane tank replacement. This usually includes:

- Non-vented safety goggles

- Insulated gloves

- Protective long sleeves

- Steel-toe boots

Please note: Replacements should only be performed by a trained individual in a well-ventilated area, away from other machinery or flammable sources.

Forklift Tank Inspections

To ensure safety and performance, tanks should be inspected:

- Before every refill

- During each replacement before mounting tanks on the lift.

- At the start of each shift

While inspecting, look for:

- Frost buildup

- Signs of a leak

- Hissing sounds

- Visible dents or rust

If you notice frost, visible damage, or the sound of hissing, take the tank out of service immediately and contact Ferrellgas or your propane provider. If there is a rotten egg odor, follow the steps outlined below.

Can you smell propane?

Propane has a strong “rotten egg” smell, thanks to an added chemical called ethyl mercaptan, which makes identifying leaks easier. If you smell gas or suspect a leak, act immediately. Leave the area right away, ensuring that everyone else does the same. Once you are at a safe distance, call 911 and Ferrellgas at 888-337-7355. Our team will respond as quickly and safely as possible.

Do not return to the area until a professional has confirmed it is safe. Your safety is the top priority, so always wait for official clearance before going back.

How to Refill Your Forklift Propane Tank

Many warehouse and distribution facility managers turn to Ferrellgas for forklift cylinder refills. The service operates much like our industry-leading Blue Rhino tank exchange service. However, unlike Blue Rhino tank exchange, our customers' forklift tanks are stored where they're used: on-site at their locations.

Forklift propane tanks are stored in special, well-ventilated cages. These cages can hold 4-12 forklift tanks, which can be accessed easily by forklift operators when they need to replace an empty tank. If you use our Auto Fill delivery service, Ferrellgas monitors your propane consumption and automatically schedules deliveries as needed, keeping local businesses humming along.

If you’re interested in a reliable and hassle-free forklift tank exchange service, we’re here to help. Our dedicated Account Managers take the time to understand your needs and recommend the plan that's right for your day-to-day. Sign up to become a customer today and get connected with a dedicated Account Manager.

Sources

Forklift Propane Safety Tips, Forklift Certification

Forklift Safety, Powered By Propane, Propane Education & Research Council

Hazardous Substance Fact Sheet, New Jersey Department of Health

How to Change a Forklift Propane Tank Safely and Prevent Worksite Accidents, CertifyMe.net

Propane Tank Handling, Yale Environmental Health & Safety

Requalification Guidance for Propane Cylinders, U.S. Department of Transportation

CATEGORIES

Archives

- Winter 2025

- Fall 2025

- Summer 2025

- Spring 2025

- Winter 2024

- Fall 2024

- Summer 2024

- Spring 2024

- Winter 2023

- Fall 2023

- Summer 2023

- Spring 2023

- Winter 2022

- Fall 2022

- Summer 2022

- Spring 2022

- Winter 2021

- Fall 2021

- Summer 2021

- Spring 2021

- Winter 2020

- Fall 2020

- Summer 2020

- Spring 2020

- Winter 2019

- Fall 2019

- Summer 2019

- Spring 2019

- Winter 2018

- Fall 2018

- Summer 2018

- Spring 2018

- Winter 2017